Sterling Bracelets

Cold forging involves hammering or forming metal at room temperature and periodically annealing to soften the metal. Non-ferrous metals including silver, brass, and copper can be cold forged, often using a blacksmith's anvil, assorted files, blades and finishing hammers. All of the bracelets shown are handwrought. They are built using tools and anvils that have been in existence for centuries. I use a 125 pound Swedish Blacksmith Anvil to create the shapes you see here. Finishing hammers are used to create and accentuate faces and edges. Files and blades assist in carving the surfaces, Polishing wheels complete the piece. Each bracelet is hallmarked with my logo and sterling silver (925) stamp.

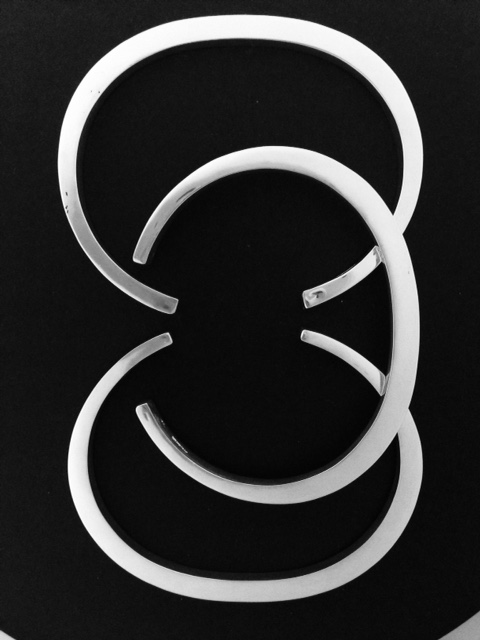

Sterling Bracelets

Cold Forging involves hammering or forming metal at room temperature and periodically annealing, to make pliable, work hardened metal. Non-ferrous metals including silver, brass, and copper can be cold forged, often using a blacksmith's anvil, assorted files, blades and finishing hammers.

Handwrought Carvings

All of the bracelets shown are handwrought. They are built using tools, hammers and anvils, that have been in existence for centuries. I use a 125 pound Swedish blacksmith anvil to create the shapes you see here. Finishing hammers are used to create and authenticate faces and edges. Files and blades assist in carving the patterns. Polishing wheels complete the process. Each bracelet is hallmarked with my logo and Sterling Silver (925) stamp.

Handwrought Bangles

All bangles are constructed and formed using solid Sterling Silver round wire, blacksmith anvil, assorted hammers, mandrils and polishing wheels. Each custom bracelet is sized according to your individual wrist measurements.

Handwrought Cuffs

Cuffs are anvil forged and formed using Sterling Silver square wire, assorted finishing hammers, mandrils and polishing wheels. A variety of textures can be applied. Each cuff is sized according to your individual wrist measurements.